1. Natural Sedatives Some owners prefer to use herbal or natural remedies that are thought to promote relaxation. Ingredients such as valerian root, chamomile, and L-theanine are popular choices. While these may be gentler on the system, their efficacy can vary.

Responsible manufacturers adhere to strict environmental guidelines to minimize the ecological footprint of their operations Responsible manufacturers adhere to strict environmental guidelines to minimize the ecological footprint of their operations

Responsible manufacturers adhere to strict environmental guidelines to minimize the ecological footprint of their operations Responsible manufacturers adhere to strict environmental guidelines to minimize the ecological footprint of their operations

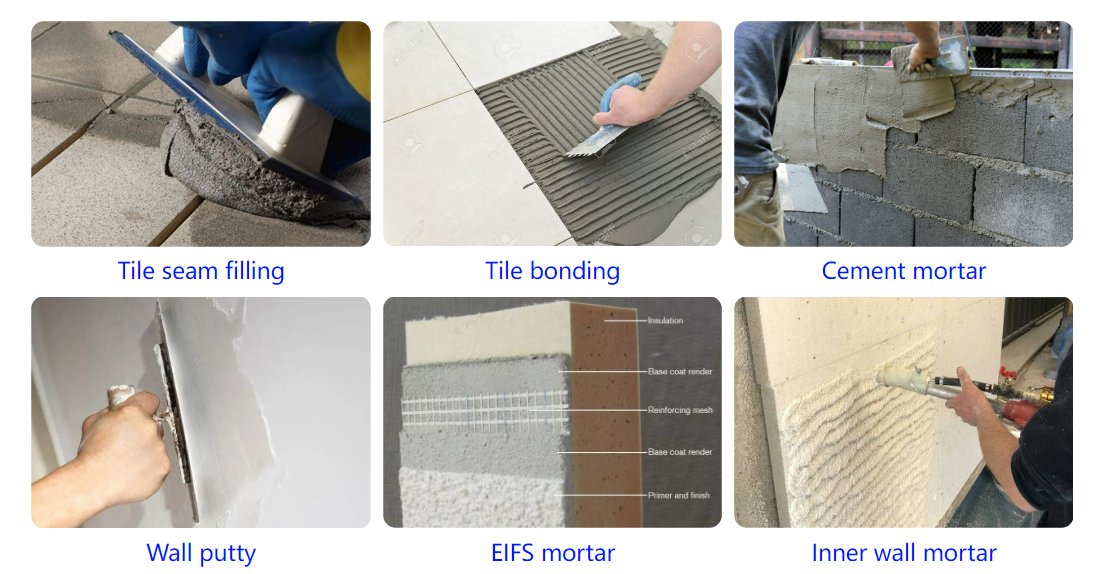

It improves the flow properties, making these materials easier to apply while providing a strong bond It improves the flow properties, making these materials easier to apply while providing a strong bond

It improves the flow properties, making these materials easier to apply while providing a strong bond It improves the flow properties, making these materials easier to apply while providing a strong bond