When to Use Charcoal Tablets

When to Use Charcoal Tablets

6. Foul-smelling Yeast Buildup As the infection worsens, a thick, dark discharge may form, often described as resembling the smell of corn chips.

If you notice any of these symptoms, it is vital to consult a veterinarian for an accurate diagnosis and treatment plan.

Medication for Nervous Dogs Understanding Options and Considerations

In addition to pharmaceutical expectorants, some natural alternatives may also provide relief. Warm fluids, honey, ginger tea, and steam inhalation can help moisten and thin mucus, making it easier to expel. Staying hydrated is essential, as sufficient fluid intake contributes significantly to mucus consistency.

- Regular Vet Check-ups Routine veterinary examinations can help catch underlying health issues before they manifest as symptoms, including diarrhea.

Understanding Albendazole Tablet Dose A Comprehensive Guide

Types of Anti-Inflammatory Tablets for Dogs

- Sneezing and nasal congestion

Important Considerations

3. Hydrogen Peroxide

Foot Rot Medicine for Goats Understanding and Treatment

When choosing a vitamin or supplement for your dog’s joint health, it’s essential to consult with a veterinarian. They can provide recommendations based on your dog’s specific needs, age, and health condition. Look for high-quality products with proven efficacy and safety standards. Many supplements require consistent use over time to see noticeable results, so patience is crucial.

For dogs, activated charcoal is typically available in tablet or powder form. It is frequently recommended by veterinarians as a treatment for certain types of poisoning or overdose situations, as it can help minimize the effects of harmful substances.

Understanding Diarrhea in Goats

While no specific antiviral treatment exists for LSD, supportive care can aid recovery and improve the welfare of affected animals. In some cases, anti-inflammatory medications can be administered to help manage fever and swelling, making the animals more comfortable. Additionally, topical treatments might be applied to the lesions to prevent secondary bacterial infections, which can exacerbate the disease and prolong recovery.

2. Dietary Adjustments Slow down dietary changes and ensure the goats have access to good-quality forage. Decreasing grain and concentrates can help stabilize their digestive system.

Benefits of Chewable Formulation

If left untreated, thrush can lead to more severe conditions, such as abscesses or even laminitis, making prompt treatment necessary.

While homeopathic remedies can be very effective, it's essential that horse owners consult with a qualified veterinarian experienced in homeopathy before starting any treatment. A thorough examination and diagnosis are crucial, as the right remedy often depends on the individual horse's symptoms and overall condition. Furthermore, some issues may require conventional medical treatment alongside homeopathy for optimal results.

Conclusion

In the field of pharmaceutics, the delivery of therapeutic agents to achieve the desired clinical effect is essential. This is made possible through various dosage forms, which serve as the means by which drugs are administered to patients. The classification of dosage forms is vital for pharmaceutical development, providing a systematic approach to understanding the characteristics and applications of each form.

Common Causes of Cough in Poultry

Classification of Pharmaceutical Dosage Forms

When to Seek Veterinary Care

What are All-in-One Dog Worming Tablets?

5. Stay Calm and Patient Remember that your dog can sense your emotions. Staying calm and patient during the process will help ease their anxiety and make the experience less stressful for both of you.

Recognizing the signs of leg pain in your dog is the first step towards addressing the problem. Symptoms may include

Horses are magnificent animals, known for their strength, speed, and grace. However, like all living beings, they can experience pain due to various factors such as injuries, arthritis, or other health conditions. Providing effective pain relief is crucial in managing a horse's health and ensuring their comfort. This article explores pain killers for horses, examining common medications, their uses, and important considerations for horse owners.

Managing a horse's anxiety and stress levels is an essential part of equine care. Whether due to competition, transportation, or changes in their environment, many horses experience anxiety that can affect their health and performance. Natural calming supplements offer a holistic approach to help soothe these nerves.

- Dry Powder Inhalers (DPIs) DPIs dispense drug particles that the patient inhales. They are popular due to their ease of use and no reliance on propellants.

If you notice these symptoms, it's essential to act quickly to address the infestation.

So, what exactly is a treat button? Essentially, it is a button that your dog can press to receive a treat as a reward. This concept is built on the principles of positive reinforcement, which is a well-established training method in which desired behaviors are encouraged through rewards. The treat button provides dogs with an engaging way to express their needs and desires, thereby promoting a more interactive relationship between pets and their owners.

Calves aged between six weeks and six months are particularly vulnerable, as their immune systems are still developing. Symptoms of pneumonia in cattle include coughing, nasal discharge, labored breathing, fever, loss of appetite, and lethargy. Prompt diagnosis and treatment are essential to prevent severe complications or death.

Understanding the Colis vs. Poultry Medicine Debate

Despite the best preventive measures, dogs can still face health challenges. Medical treatments vary depending on the condition. Common health issues in dogs include skin allergies, ear infections, and gastrointestinal problems.

Causes of Horse Asthma

Types of Ventilation Systems

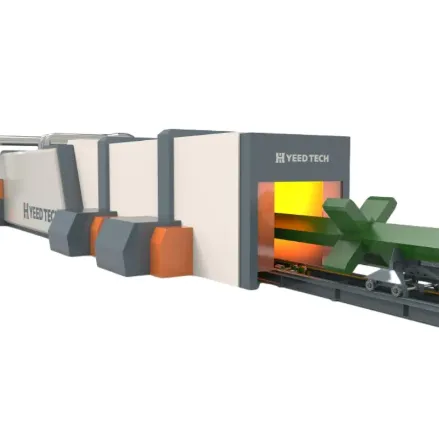

These systems utilize programmable settings that adjust to the specific needs of the material, whether it’s structural beams or intricate steel components. As a result, manufacturers can maintain uniformity across diverse projects, enhancing the reliability of their products.

The versatility and efficiency of automatic paint spray machines have made them an essential tool for industries seeking high-quality, sustainable, and cost-effective coating solutions. With advancements in automatic paint spraying robots and automatic paint spraying equipment projects, manufacturers can now achieve unparalleled precision, consistency, and customization. As industries continue to evolve, the adoption of automatic paint spraying machines ensures that businesses stay ahead of the curve, meeting diverse needs while prioritizing efficiency and environmental responsibility. Whether it’s for tailored solutions or streamlined production, these machines represent the future of industrial painting technology.

In today’s manufacturing industry, productivity is key. Achieving seamless results while maintaining efficiency requires modern equipment that can keep up with high demands. Automated welding arms have become a staple in this pursuit, revolutionizing the way industries approach welding tasks. These robotic arms are designed for precision, speed, and consistency, ensuring that every weld is up to standard without the need for constant manual intervention.

Steel structures, known for their strength and longevity, require proper maintenance to withstand the elements and retain their visual appeal over time. One of the most effective methods for protecting and enhancing these structures is steel structure painting. This process not only improves the aesthetic quality of buildings and bridges but also plays a crucial role in extending the life of steel by preventing corrosion.

- Airless Spray Utilizing high pressure to atomize the paint, this method is often used for thicker materials and large surface areas, making it ideal for industrial applications.

As industries continue to prioritize worker health and safety, the significance of implementing a Welding Fume Extraction System cannot be overstated. Not only does it protect workers from hazardous exposure, but it also enhances overall productivity and equipment longevity. By investing in such systems, companies not only ensure compliance with health regulations but also foster a safer, more efficient workplace. The future of welding, therefore, lies not only in innovation in welding techniques and technologies but also in creating an environment where workers can thrive without the threat of harmful fumes.

1. Research and Development Conduct thorough research on the latest robotic and spraying technologies, assessing various paint materials and their compatibility with automation.

Applications of Portable Fume Collectors

Exploring the Functionality and Advantages of Telescopic Container Handlers

4. Reduced Material Waste By providing accurate cuts, H-beam cutting machines help minimize material waste. This efficiency not only saves costs but also supports sustainable practices in the industry by reducing excess scrap.

When choosing a portable welding fume extractor, several factors should be considered

3. Reduced Damage Containers protect materials during transport, helping to minimize damage due to impact or exposure to elements, thus lowering overall replacement costs.

A wall-mounted welding exhaust fan is a ventilation device specifically designed to remove contaminated air from welding areas. These fans are typically installed in a wall or window and are strategically positioned to capture harmful fumes and gases generated during welding operations. Most wall-mounted fans are equipped with high-capacity motors and durable construction to withstand the harsh conditions of welding environments.

- Manufacturing Used for transporting raw materials and finished products within production facilities.

5. Fire Resistance Steel is inherently non-combustible, offering robust fire resistance—a critical factor in building safety. With appropriate fireproofing treatments, steel floor systems can meet stringent safety regulations, further enhancing their desirability in multifamily residential, commercial, and high-rise buildings.

The Importance of Fume Extraction

The Steel Floor System An Overview

Automatic spray painting machines have emerged as a transformative development in the realm of modern manufacturing and surface finishing. These machines, revered for their efficiency and precision, are designed to cater to a variety of industries, ranging from automotive and aerospace to furniture and electronics, revolutionizing the traditional painting process.

Factors to Consider When Selecting a Manufacturer

The welding process releases fumes containing various harmful substances, including metallic oxides, silicates, and gases like ozone and nitrogen dioxide. Prolonged exposure to these fumes can pose serious health risks to welders, including respiratory issues, irritation of the eyes and throat, and long-term conditions such as lung cancer. Using an exhaust arm can significantly reduce these risks by ensuring that harmful fumes are promptly captured and removed from the work area.

The Górny Podnośnik exemplifies the intersection of innovation and practicality in the lifting industry. With its robust features, emphasis on safety, and wide-ranging applications, it is no wonder that this upper lift system is becoming increasingly popular in various sectors. As industries continue to evolve, technologies like the Górny Podnośnik will remain at the forefront, enhancing productivity and ensuring a safer working environment for all. With a focus on efficiency, safety, and ergonomic design, the future looks bright for lifting technologies like the Górny Podnośnik, paving the way for more advanced solutions in the years to come.

A major advantage of automatic paint sprayer machines is their ability to deliver uniform coatings across all surfaces. Unlike manual methods, these machines minimize human error, resulting in smoother finishes and reduced rework.

The integration of an automatic spray painting system with conveyor further enhances this efficiency by automating the movement of items through the painting process. This eliminates bottlenecks and ensures a seamless workflow, making these systems ideal for high-volume production lines. Additionally, the precise application of paint minimizes material waste, leading to cost savings and a more sustainable operation.

How Do They Work?

- Wall-Mounted Collectors These fixed units are ideal for workshops with dedicated welding stations. They capture fumes from fixed workstations and are often more powerful than portable units.

However, while automation increases efficiency, it also requires a clean, safe environment to maintain optimal performance. This is where a portable welding ventilation system comes into play. Ensuring proper air quality can improve not just the effectiveness of the welding arms, but also worker health and the longevity of the machinery itself.

When metals are fused together through welding, high temperatures vaporize the metal, generating fumes that are often hazardous to human health. Common materials involved in welding, such as mild steel, stainless steel, and aluminum, release various toxic substances, including manganese, lead, and chromium. Prolonged exposure to these fumes can result in conditions such as “metal fume fever,” chronic bronchitis, reduced lung function, and even more severe illnesses like cancer.

Conclusion

ما هو نظام mobil rökutsugsenhet؟

Automatic spray painting machines are revolutionizing how industries approach coating processes, particularly in the realm of steel structure manufacturing equipment. By delivering consistent, high-quality finishes and streamlining pre-treatment with steel structure surface treatment equipment, these systems improve efficiency and product reliability. For manufacturers dealing with steel component spray painting, the combination of automation and advanced technology ensures precision and durability. As industries continue to embrace innovation, automatic spray painting machines will remain at the forefront, simplifying production and raising the bar for quality.

In modern manufacturing, achieving efficiency, precision, and consistent quality is paramount. The automatic spraying line has emerged as a transformative solution, revolutionizing production processes across industries. By automating the application of coatings, paints, and finishes, these systems not only streamline workflows but also enhance product quality and reduce waste.

5. Экономия пространства Поскольку портативные устройства могут использоваться по мере необходимости и не требуют постоянной установки, они идеально подходят для малых и средних производств, где каждая квадратная метра имеет значение.

4. Noise Levels Consider the noise produced by the extractor, as excessive noise can be distracting and contribute to a stressful working environment.

The adoption of automatic paint dispensers is not merely a trend but a strategic move towards enhancing operational efficiency and achieving superior outcomes. Its role in optimizing the painting process is invaluable, reducing time spent on manual mixing and application errors. As businesses continue to prioritize efficiency and quality, the implementation of such advanced tools becomes indispensable.

Shipping companies must adhere to strict international safety standards to ensure the integrity of their operations. The International Maritime Organization (IMO) and the International Organization for Standardization (ISO) have established guidelines governing the safe loading and stacking of shipping containers. Stacking bars are specifically designed to comply with these regulations, highlighting their critical role in maintaining safety across the maritime shipping industry.