Understanding Hydroxyethyl Cellulose Composition, Properties, and Applications

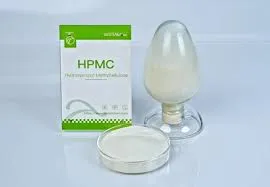

HPMC is a semi-synthetic polymer derived from cellulose, a natural biopolymer. The modification process involves hydroxypropyl and methyl groups, enhancing its solubility in water and organic solvents. This versatility allows HPMC to be used in various pharmaceutical applications, including tablet binding, thickening agents, controlled-release formulations, and stabilizers for emulsions.

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose—that most abundant organic polymer found in nature. Thanks to its unique properties, HEC has found a wide range of applications across various industries, including pharmaceuticals, cosmetics, food, and construction. With an increasing demand for HEC in diverse applications, the market for hydroxyethyl cellulose for sale is growing steadily.

Although raw materials of Pig meat and bovine meat still play the dominant role in the market, the market share of HPMC will increase in the future. Other types of capsules click Different Types of Capsules to view details.

Despite its widespread utility, the production of HPMC must be approached with consideration for environmental impact. As interest in sustainable materials grows, researchers are exploring greener production methods and assessing the lifecycle of HPMC to minimize its carbon footprint. Innovations in cellulose modification and bio-based alternatives are being developed to ensure that HPMC continues to meet modern demands while adhering to environmental standards.

The pharmaceutical and cosmetic industries also recognize the value of MHEC due to its ability to form gels and stabilize emulsions. In pharmaceuticals, it serves as a binder in tablet formulations and as a thickening agent in topical preparations, ensuring that active ingredients are delivered effectively. The cosmetic sector benefits from MHEC in formulations like creams and lotions, where it aids in achieving the ideal texture and consistency, enhancing user experience.

Hydroxypropyl methylcellulose (HPMC) is a versatile and widely used compound in various industries, including pharmaceuticals, food, cosmetics, and construction. As a cellulose derivative, it is non-toxic, biodegradable, and provides a range of functional properties, making it a preferred choice for many applications. If you’re considering purchasing HPMC, understanding its uses, properties, and purchasing options is crucial for making an informed decision.

HPMC is produced by chemically modifying cellulose, a natural polymer found in plant cell walls. The modification involves the substitution of hydroxyl groups in cellulose with hydroxypropyl and methyl groups, resulting in a compound that retains the structural characteristics of cellulose while enhancing its solubility in aqueous solutions. The degree of substitution and the molecular weight of HPMC significantly influence its solubility and viscosity, making it a customizable option for various applications.

hpmc 200000.

1. Low Viscosity Low viscosity HPMC usually ranges from 1000 to 6000 mPa.s. These grades are typically used when a thinner consistency is required, such as in liquid formulations or low-viscosity pastes. They offer excellent spreadability and are often used in applications where high dilution is necessary.

hpmc viscosity grades

Significance of Tg in Applications

4. Adhesion

Additionally, HPMC is non-toxic and biocompatible, making it safe for ingestion in pharmaceutical applications. Its stability under various pH conditions allows it to be utilized in a wide range of formulations, from solid dosage forms like tablets and capsules to liquid formulations such as suspensions and emulsions.

In conclusion, the gelation temperature of Hydroxypropyl Methylcellulose is a critical parameter that impacts its functionality in various applications. Understanding the factors that influence this property allows formulators to optimize HPMC-based products for better performance and stability. As demand for versatile and effective products continues to grow across multiple industries, mastering the science of HPMC gelation will remain an essential aspect for researchers and manufacturers alike. The ongoing study of HPMC and its gelation behavior will undoubtedly lead to innovative solutions that meet the evolving needs of consumers and industries worldwide.

The choice between HEC and HPMC is often dictated by the specific requirements of the formulation. HEC is predominantly used in personal care items, such as shampoos, conditioners, and skin care products. Its ability to provide a non-stick feel and excellent moisture retention makes it an ideal ingredient in these applications. Additionally, HEC is utilized in the construction industry as a viscosity modifier in tile adhesives and mortars, where it helps to improve workability and extend open time.

hec vs hpmc

Hydroxypropyl Methylcellulose (HPMC) is a widely used polymer in various industries, including pharmaceuticals, food, cosmetics, and construction. Its unique properties, such as thickness, film-forming ability, and emulsification, make it an ideal ingredient in many formulations. One of the most commonly discussed properties of HPMC is its solubility in cold water, which plays a critical role in determining its application efficacy.

Why Choose Chinese Suppliers?

Understanding Redispersible Latex Powder Manufacturers

3. Storage and Stability HEC should be stored in a cool, dry place away from direct sunlight and incompatible materials. Proper storage ensures the stability and usability of the product over extended periods.