3. Skin Infections Used to treat complicated skin and soft tissue infections caused by susceptible organisms.

3. Skin Infections Used to treat complicated skin and soft tissue infections caused by susceptible organisms.

- Monitor Symptoms Keep a close eye on your dog’s condition. If diarrhea persists for more than a day, or if your dog exhibits other worrying symptoms, such as vomiting or changes in appetite, seek veterinary care promptly.

Symptoms of Horse Allergies

3. Parasites Internal parasites, such as roundworms and tapeworms, can irritate the gut lining, leading to diarrhea. Regular deworming protocols are essential for controlling these parasites.

5. Herbal Remedies Certain herbs, such as chamomile and ginger, have natural antihistamine properties and can soothe irritated mucous membranes. Herbal formulations that combine several of these ingredients can often provide comprehensive support for allergic horses.

Expectorants work by thinning and loosening mucus in the airways, thereby facilitating its expulsion when coughing. This process not only helps clear the airways but also promotes better breathing and comfort. Generally, the primary active ingredient in expectorants is guaifenesin, a well-known compound found in many over-the-counter medications. It is important to note that while expectorants help relieve symptoms, they do not cure illnesses. Instead, they support the body’s natural healing processes.

Medications for Managing Drooling

Coconut oil is a highly effective home remedy for dry skin in horses. It has moisturizing properties and contains fatty acids that help nourish the skin. To use, warm a small amount of coconut oil in your hands and massage it into the affected areas. Not only does it hydrate the skin, but its antibacterial and antifungal properties can also help prevent infections.

Effective pain management in sheep is vital for their welfare and productivity. By understanding the nature of pain and employing a combination of pharmacological and non-pharmacological strategies, producers can ensure that their flock remains healthy and receives the necessary care to thrive. The ongoing research and development in this area will continue to enhance the practices for managing pain in sheep, ultimately leading to better outcomes for animals and the agricultural industry as a whole. As awareness increases, it is crucial for farmers and veterinarians to collaborate closely, ensuring that pain medicine becomes an integral part of ovine health management.

The Importance of Worming Your Dog

4. Supports Digestive Health

Homeopathy is another alternative approach that is gaining popularity among horse owners. This system of medicine uses highly diluted substances to stimulate the horse's own healing processes. Homeopathic remedies can be tailored to the individual horse, taking into account its unique symptoms, temperament, and overall health. While some owners report positive outcomes, scientific evidence supporting homeopathic treatment remains limited, and it is essential to work with a qualified practitioner.

Inflammation is a natural immune response that occurs in dogs just like in humans. It can be triggered by a variety of factors including injury, infection, or chronic conditions. While inflammation can be beneficial in the short term, when it becomes chronic, it can lead to discomfort and health issues. For dog owners, managing their pet's inflammation is crucial for maintaining their quality of life. Over-the-counter (OTC) anti-inflammatory medications are one such option that can assist in this regard. However, it is important for pet owners to understand the dos and don’ts of using these products.

1. Allergies Patients with a known allergy to penicillin or cephalosporins should avoid amoxicillin as it may trigger allergic reactions, ranging from mild rashes to severe anaphylaxis.

Common Causes of Nausea in Dogs

Puppies bring an unparalleled joy into our lives, filling our homes with laughter, energy, and unconditional love. However, along with the excitement of bringing a new puppy into your family comes the responsibility of ensuring their health and well-being. Many new puppy owners quickly discover the importance of “puppy fever medicine,” a catch-all term for the various vaccinations, medications, and preventative care necessary to keep their energetic companions healthy and safe.

When a horse presents with a cough, it is crucial to identify the underlying cause. A thorough veterinary examination will typically include

Basic Wound Care at Home

Conclusion

Cow lice are external parasites that infest cattle, feeding on the animal's blood and skin. There are several species of lice that can affect cows, with two primary types being biting lice and suction lice. Biting lice feed on dead skin and debris, while suction lice attach themselves to the skin and feed on the host’s blood. Infestations can lead to severe itching, hair loss, and skin irritation, ultimately affecting the animal's health and growth.

Vitamin E

Despite the importance of vitamins, they are not always present in adequate amounts in cow diets. Factors like poor forage quality, inadequate feeding practices, and environmental conditions can lead to vitamin deficiencies. Hence, utilizing vitamin medicines through commercial supplements can help bridge these nutritional gaps.

Medical Treatments

There are various disinfectants available for veterinary use, each with unique properties and applications. The most common types include

Potential Side Effects

B Vitamins

Sodium hypochlorite, popularly known as bleach, is a powerful disinfectant with robust efficacy against bacteria, viruses, and fungi. It is often used in diluted forms (typically 110 or 1100) for various disinfection tasks, such as cleaning cages, surgical instruments, and floors. The mode of action involves the oxidation of proteins and other cellular components, leading to microbial cell death. While sodium hypochlorite is highly effective, it can be corrosive to certain materials and is irritating to the skin and respiratory tract, necessitating careful handling and thorough rinsing of surfaces after use.

Calcium powder is commonly utilized in veterinary practice to supplement the diets of various animals. It is particularly prevalent in the nutrition of livestock, pets, and exotic animals. For instance, dairy cattle often require calcium supplements to support milk production and maintain overall health. Similarly, calcium powder is frequently added to the diets of dogs, cats, and other pets, especially those that are pregnant, nursing, or recovering from an illness.

In addition to products, poultry medicine suppliers provide essential services, including consultation and training for poultry producers. They help farmers understand the importance of biosecurity measures, which are crucial for preventing the introduction and spread of diseases within flocks. By educating producers about best practices in animal husbandry, suppliers play a pivotal role in enhancing flock health and welfare.

6. Marek’s Disease A viral disease caused by a herpesvirus, Marek's can cause tumors and affect the nervous system of chickens. Vaccination at a young age is crucial to control the spread of this disease.

Treatment Options

Rotational grazing and strategic dosing are essential strategies in managing parasite resistance. Overuse of dewormers can lead to the development of resistant parasite populations, making treatment increasingly difficult. Farmers are encouraged to implement a targeted treatment plan based on careful monitoring of fecal egg counts and the clinical signs of parasitism. This approach helps minimize the use of medicines while effectively controlling parasite populations.

- Improving Overall Comfort By mitigating allergic reactions, these medications help horses become more comfortable, promoting a healthier lifestyle and facilitating better training and performance.

It is generally recommended to start worming your puppy at an early age. Most veterinarians suggest that puppies should be wormed for the first time at two weeks of age, followed by treatments every two weeks until they are twelve weeks old. After this initial period, worming should continue every three months or as directed by your vet.

As research continues to uncover the benefits of blue medicine, its role in equine wellness will likely expand. With growing evidence supporting its efficacy, more equine practitioners may adopt this treatment as a standard part of their care protocols. Furthermore, advancements in technology are allowing for more user-friendly devices, making it easier for horse owners to administer blue light therapy on their own.

Horses are majestic creatures known for their grace, strength, and beauty. However, many horse owners and trainers often encounter a less idyllic side to these animals anxiety. Just like humans, horses can experience stress and anxiety, which can significantly affect their behavior, performance, and overall well-being. Understanding horse anxiety and exploring medication options can be vital for ensuring that these magnificent animals lead a calm and fulfilling life.

In addition to topical treatments, injectable dewormers can also be effective in treating lice infestations. Ivermectin, moxidectin, and other anthelmintics targeting ectoparasites are commonly used. These treatments not only combat lice but also provide broader protections against other parasites, enhancing overall herd health.

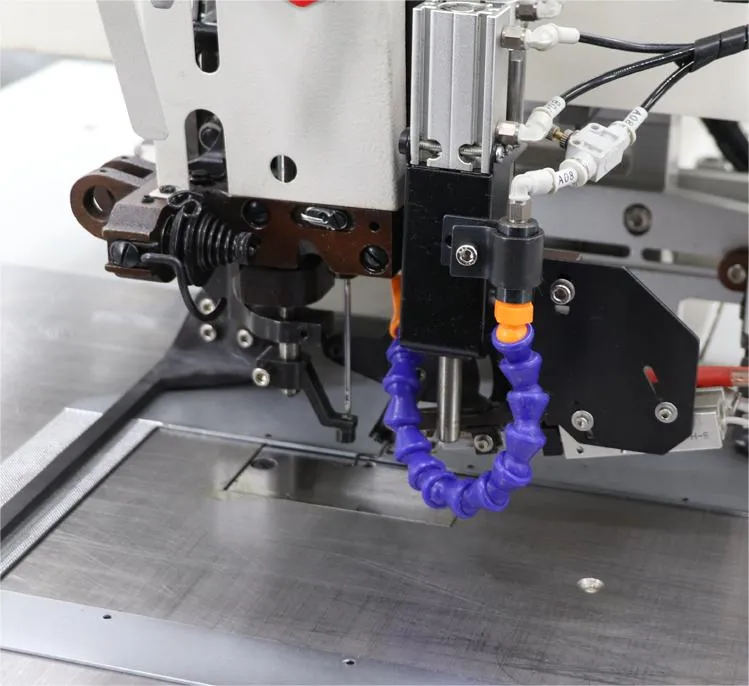

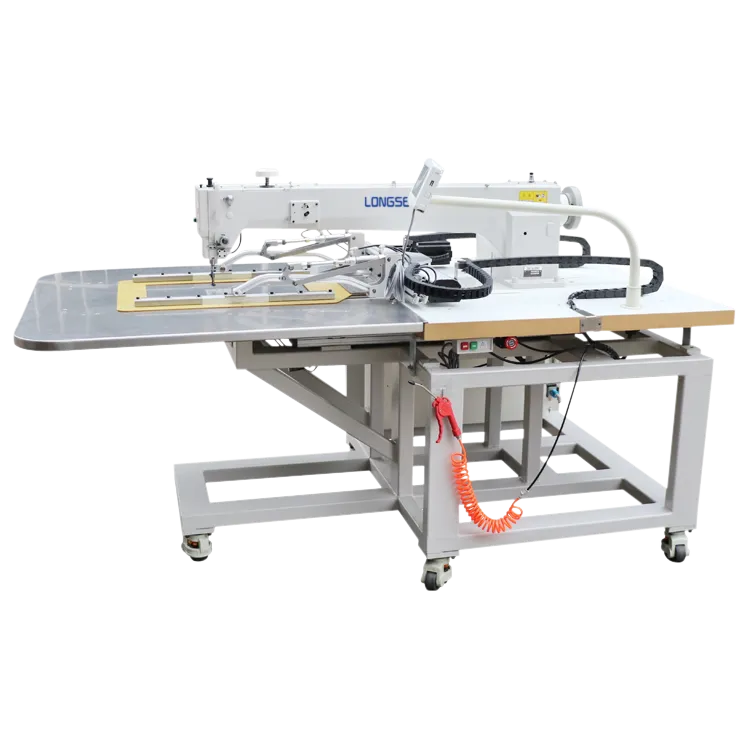

3. Heavy-Duty Needles These machines often come with specially designed needles that can penetrate thick fabric layers with ease. The right needle is crucial in upholstery, as it affects the stitch quality and the overall finish of the product.

Now that your machine is set up, you can start sewing. Engage the presser foot and start stitching slowly. Keep a steady pace to ensure even stitching, and avoid pulling the fabric to prevent skipped stitches. Regularly check your stitching to ensure that both threads are flowing smoothly and that there are no tangles.

The Pricing Spectrum

Conclusion

1. Increased Efficiency The capability to create two lines of stitching in one pass significantly boosts production speed. This efficiency is especially beneficial in high-volume manufacturing environments, where time is a critical factor.

- Future Scalability A vision for growth can inform the decision on whether to invest in a particular machine. Choosing a machine that allows for future upgrades or adjustments can save costs in the long run.

To ensure optimal performance, regular maintenance of heavy duty sewing machine motors is necessary. This includes routine cleaning, lubrication, and inspection of belts and gears. By addressing minor issues before they develop into significant problems, users can extend the lifespan of their machines and maintain consistent sewing quality.

1. Features and Functionality

3. Juki TL-2010Q This professional-grade machine is perfect for quilting and leatherwork. It has a powerful motor, a large throat space, and is designed for high-performance sewing.

The biggest difference between the two is the reason why they were built. For example, if you purchase a regular machine, you are looking for something that you will be able to use around the house. For example, you might want to mend clothes or create your own patterns. However, a heavy-duty machine was made to be used by a commercial business. This means that they will need to be able to work on a wider range of projects. Because they are designed to run for a long time, the components have been strengthened. In addition, heavy-duty machines tend to offer more advanced sewing options.

The zigzag stitch is another defining feature of this sewing machine. This stitch offers incredible flexibility, enabling seamstresses to create a variety of finishes and designs. It can be used to secure seams, finish raw edges, create decorative patterns, and even appliqué. The ability to adjust the width and length of the zigzag also means that sewing enthusiasts can customize stitches to suit their projects—whether that’s heavy upholstery, delicate garments, or quilting.

What is Lock Stitch?

One of the key features of a woven sack sewing machine is its speed and efficiency. These machines are designed to work quickly and accurately, allowing for high volume production of woven sacks. This is essential for industries that require large quantities of sacks to package their goods for distribution.

4. Cost-Effective Although the initial investment in an industrial overlocker may be higher than a standard sewing machine, the long-term benefits, including reduced labor costs and improved fabric usage, can lead to significant savings.

What is a Double Needle Walking Foot Sewing Machine?

Multi needle quilting machines are inherently versatile, providing quilters with the ability to explore a wide array of designs and techniques. With multiple needle systems, quilters can easily switch between different thread colors and types within a single project. This allows for complex designs, intricate motifs, and personalized embellishments that would typically be challenging to achieve by hand. Additionally, many multi needle machines come with built-in design software that offers a library of patterns, enabling users to choose and customize designs at their fingertips.

Computerized long arms, often referred to as robotic arms or automated manipulators, are essentially mechanical devices that can be programmed to perform a variety of tasks. They are equipped with multiple joints and segments, allowing for a high degree of flexibility and movement. The 'long arm' aspect pertains to their extended reach, enabling them to perform tasks that would be challenging or impossible for human workers. Typically, these robotic arms utilize advanced software and artificial intelligence to execute complex motions with speed and accuracy.

The Art of Lock Sewing A Comprehensive Guide

Choosing the Right Sewing Machine for Boat Upholstery

1. Standard Foot This is the most common presser foot, ideal for general sewing tasks. It works well for straight stitching and basic construction, making it suitable for beginners learning to sew.