Importance of Veterinary Guidance

Importance of Veterinary Guidance

The Use of Antibiotics in Sheep Farming

Understanding Diarrhea in Goats

There are multiple factors that can lead to a horse developing a cough. Some of the most common include

What is the Heat Cycle in Dogs?

3. Probiotics Administering probiotics can help restore balance to the gut's flora, especially after treatments with antibiotics or during stress.

In summary, diarrhea in puppies is a manageable condition when approached promptly and correctly. Observing your pet’s behavior and physical health will guide you in determining when veterinary intervention is necessary. With appropriate care, most puppies will recover quickly, allowing them to return to their playful selves in no time.

Before diving into treatment options, it’s essential to recognize the signs of nausea in dogs. A dog experiencing nausea might display several behaviors, including drooling, licking their lips, reluctance to eat, vomiting, pacing, or even hiding. If you notice these symptoms alongside other signs of distress, it’s vital to consult your veterinarian to determine the cause of nausea and appropriate treatment options.

3. Foot and Mouth Disease (FMD) This viral disease is highly contagious among cattle and can lead to severe economic losses in the livestock industry. Vaccination programs are essential in controlling its spread, particularly in regions prone to outbreaks.

Conclusion

Certain vitamins and nutrients have been found to support kidney function and overall health. Here are some of the key vitamins and supplements beneficial for canine kidney health

In conclusion, while diarrhea in goats can be concerning, understanding the causes and symptoms can empower owners to take effective action. With prompt and appropriate treatment, many goats can recover quickly and return to their healthy, playful selves. Regular preventive measures will further enhance the health and well-being of your goats, ensuring they thrive in your care.

Puppy Vitamins and Supplements Ensuring a Healthy Start for Your Furry Friend

Understanding Albendazole Chewable Tablets Uses, Benefits, and Considerations

Resistance Concerns

- Manual Administration In some cases, it may be necessary to administer the tablet manually. This involves opening the pet's mouth and placing the tablet at the back of the throat, followed by gently closing the mouth and encouraging swallowing.

The Significance of Cows in Medicine

3. Nutrition Provide a balanced diet that meets the nutritional needs of pigs at various growth stages. Avoid abrupt changes in diet and monitor feed quality to prevent digestive disturbances.

Farmers must look out for several symptoms indicative of diarrhea in their flocks. These include frequent loose droppings, lethargy, decreased feed and water intake, ruffled feathers, and, in severe cases, dehydration. Chickens suffering from diarrhea may also exhibit signs of distress or discomfort, which warrants immediate attention.

Digestive Health

There are many types of medications available for dogs, and they can generally be categorized into several groups based on their function

3. Anti-inflammatory Drugs In some cases, anti-inflammatory medications, such as non-steroidal anti-inflammatory drugs (NSAIDs), may be prescribed to reduce respiratory distress and improve the overall well-being of the affected birds.

Conclusion

The impact of parasites on sheep is profound. Infected sheep often show reduced growth rates, lower reproductive performance, and a decrease in wool quality. The presence of parasites also increases the farmer's production costs related to veterinary care, additional feeding to compensate for lost nutrients, and potential losses from unproductive or dead animals. Therefore, managing parasites is not only essential for animal health but also for the economic viability of sheep farming operations.

Benefits of Dog Vomit Tablets

In conclusion, effective pain medicine for cows is an indispensable part of veterinary care that enhances animal welfare and productivity. Continued research into pain management options, combined with increased education for stakeholders in the cattle industry, will pave the way for better practices and a heightened understanding of the importance of pain relief. Moving forward, it is crucial for livestock producers to recognize that the well-being of their animals directly correlates with the success of their operations, making pain management not just an ethical consideration but also a business imperative.

One of the primary aspects of cattle veterinary medicine is preventive health care. This includes vaccination programs to protect against infectious diseases such as brucellosis, bovine viral diarrhea (BVD), and infectious bovine rhinotracheitis (IBR). Regular vaccinations are essential in maintaining herd health and preventing outbreaks that could have devastating effects on cattle populations and farmers' incomes. Furthermore, routine health checks enable early detection of potential health issues, allowing for timely intervention.

Treating Foot Rot

Conclusion

Foot rot is primarily caused by two types of bacteria Fusobacterium necrophorum and Dichelobacter nodosus. These pathogens invade the soft tissue between the toes of the goat's hooves, leading to inflammation, pain, and, if left untreated, severe tissue damage. Goats that are stressed, housed in unsanitary conditions, or have compromised immune systems are more susceptible to infection.

- Coated Tablets These tablets have a protective coating that can help mask the taste or facilitate easier swallowing.

5. Regular Veterinary Check-Ups Regular vet visits can help identify early signs of dental problems. Your veterinarian may recommend specific dental care products or routines based on your dog’s needs.

Puppies have unique nutritional requirements compared to adult dogs. They are in a critical growth phase, and their bodies need essential vitamins and minerals to support healthy development. Key nutrients such as calcium, phosphorus, protein, and various vitamins play pivotal roles in their bone development, immune function, and overall vitality. However, while a well-balanced puppy food is designed to meet these needs, some puppies may benefit from additional supplementation.

Horse worm medications, often referred to as anthelmintics, fall into several classes, each effective against different types of parasites. The most common types include

Administering puppy worm tablets is generally stress-free, especially when you introduce them to your puppy at an early age. Most tablets can be disguised in your puppy's food or given as a treat, making them more palatable. It's essential to follow the dosing instructions provided by your veterinarian carefully, as they will vary depending on your puppy's age and weight. Regular veterinary check-ups will also help monitor your puppy's health and ensure that the treatment is working effectively.

An essential aspect of goat health management is preventive care. Routine vaccinations and deworming protocols are critical components of a successful goat farming operation. By proactively managing health, farmers can reduce the incidence of diseases that often lead to costly treatments or, worse, loss of livestock.

These medications can provide relief, but they are most effective when combined with behavioral therapies and training.

Goats are versatile animals that require proper nutrition and care to promote optimal growth and weight gain. In the livestock industry, particularly in goat farming, achieving healthy weight gain is critical for enhancing productivity and ensuring the overall well-being of the animals. This article discusses various weight gain medicines and supplements for goats, along with essential management practices to achieve targeted weight gain.

Before administering any anti-inflammatory drug, it is crucial for horse owners to consult with a veterinarian. A thorough examination and appropriate diagnostic workup should precede the use of these medications to ensure that they are indicated and that potential risks are managed effectively.

Furthermore, the adaptability of these systems is a point of expertise worthy of note. Sectors such as furniture manufacturing and heavy machinery have unique requirements; automatic systems can be programmed for a myriad of settings, accommodating different paint viscosities and surface types. The expertise embedded in these solutions is evident—they offer industry-specific customizations, which ensure optimal performance and quality.

Whether it’s a wall mounted welding fume extractor for smaller workshops or a more complex central fume exhaust system for larger operations, these solutions offer effective means of keeping the air clean. Integrating a fume ventilation system directly with the robotic welders enhances the overall performance of both the system and the workers, promoting a healthier work environment and improving the longevity of the equipment.

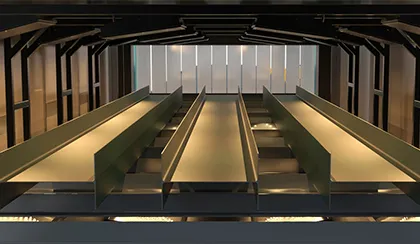

One of the primary reasons industries are adopting automated spray painting machines is their ability to streamline production processes. Unlike manual painting methods, these machines are capable of operating continuously with minimal human intervention. This ensures that large volumes of products can be coated efficiently, reducing production downtime.

3. Improved Air Quality By effectively removing fumes from the workspace, these extraction systems enhance overall air quality. A cleaner environment not only protects the health of workers but also boosts productivity, as employees can work more efficiently in a well-ventilated area.

When it comes to authority and trustworthiness, manufacturers of automatic paint dispensers have proven their credibility through certifications and adherence to industry standards. Many of these companies work closely with paint manufacturers to ensure that their products are compatible with a variety of paint types—latex, acrylic, oil-based, and more. This collaboration further assures end users of the dispenser's reliability and effectiveness, reinforcing its role as an essential tool in professional painting.

3. Monitoring Air Quality Implementing air quality monitoring systems can provide real-time data on fume levels, helping employers identify potential hazards before they become significant health issues.

1. Health and Safety Compliance Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA), have established permissible exposure limits for airborne contaminants. An effective WFES helps companies comply with these regulations, thereby safeguarding the health of their workforce.

Risk Management and Security

While the initial investment in automatic spray painting technology can be substantial, the long-term savings often outweigh the costs. Automated systems reduce labor costs, as fewer workers are needed to operate machinery and monitor processes. Additionally, the precision of these systems minimizes paint wastage, which can significantly impact material expenses over time.

The Importance of Welding Ventilation

4. Local Exhaust Ventilation (LEV) Systems LEV systems offer a comprehensive solution, combining several elements such as hoods, ducts, and fans to efficiently capture and remove airborne contaminants directly at the source.

When metals are fused together through welding, high temperatures vaporize the metal, generating fumes that are often hazardous to human health. Common materials involved in welding, such as mild steel, stainless steel, and aluminum, release various toxic substances, including manganese, lead, and chromium. Prolonged exposure to these fumes can result in conditions such as “metal fume fever,” chronic bronchitis, reduced lung function, and even more severe illnesses like cancer.

Each unit is built with the latest technology, ensuring efficient airflow and maximum filtration. Whether you work in a large manufacturing facility or a small workshop, our welding fume extractors provide a comprehensive solution to manage and eliminate dangerous fumes safely and effectively.

The Importance of ISO Containers

In the world of logistics and transportation, container loading platforms play a crucial role in facilitating the smooth transfer of goods between different modes of transport. Whether it's shipping containers to and from ships, trucks, or trains, the efficiency of these operations directly influences the overall supply chain. As global trade continues to expand, the need for effective container loading solutions has become even more glaring, prompting innovations and improvements in this area.

The Importance of Air Extractors in Welding

En plus des grues, il existe d'autres équipements de levage, comme les chariots élévateurs et les gerbeurs. Les chariots élévateurs sont souvent utilisés pour déplacer des conteneurs dans les entrepôts ou sur le site d'un port. Ils sont dotés de fourches qui peuvent soulever et déplacer des conteneurs, permettant ainsi une flexibilité dans la gestion des marchandises. Les gerbeurs, quant à eux, sont utilisés pour empiler des conteneurs à des hauteurs plus élevées, ce qui optimise l'espace de stockage.

4. Compliance and Standards Many containers adhere to industry standards for safety and environmental compliance, contributing to a company's adherence to regulations.

Bunday tizimlar ishchilarning salomatligini ta'minlash uchun juda muhimdir. Ular nafaqat ishchilarni zararli moddalar ta'siridan himoya qiladi, balki ishlab chiqarish jarayonida xavfsizlikni ham oshiradi. Shu bilan birga, ular atrof-muhitga ham ijobiy ta'sir ko'rsatadi, chunki zararlilik kirishini kamaytiradi.

Industries today require coating solutions that can handle a wide array of applications, and automatic paint spray machines excel in meeting this demand. These machines are engineered to adapt to different surface types, materials, and finishes, ensuring flawless results every time.

In the welding industry, health and safety are paramount concerns. One of the critical challenges that welders face is exposure to harmful fumes generated during the welding process. These fumes consist of various toxic metals and gases that can pose serious health risks if inhaled over an extended period. This is where a welding fume extractor comes into play. These specialized devices play a vital role in improving air quality and safeguarding the health of workers in welding environments.

3. Enhanced Productivity A clean working environment translates to enhanced worker comfort and morale. When employees feel safe and are not hindered by poor air quality, their productivity and efficiency can significantly increase.

What sets automated spray coating systems apart is their integration of advanced technology

. Utilizing sensors and data analytics, these systems monitor and adjust parameters in real-time, ensuring optimal application conditions. This level of expertise ensures that each product receives the exact intended finish, thereby enhancing durability and aesthetic appeal.

2. Filtration Once captured, the fumes and dust are passed through a series of filters. HEPA (High-Efficiency Particulate Air) filters are commonly used, as they can trap particles as small as 0.3 microns with an efficiency of 99.97%. Depending on the specific needs of the operation, additional filters for chemical fumes may also be employed.

For businesses seeking to elevate their production capabilities, embracing automatic paint spraying equipment is a strategic move that promises to deliver both immediate and long-term benefits. As industries continue to evolve, driven by technological advancements and market dynamics, the ability to adopt and leverage such state-of-the-art machinery will define competitive advantage. Innovators and operations managers who prioritize quality, efficiency, and sustainability will find automatic paint spraying equipment to be a critical asset, aligning with industry best practices and setting new benchmarks for excellence.

Understanding Container Lifting Machine Prices

What is a Steel Floor System?

4. Specialty Rods Specialty rods, including those for aluminum or high-temperature applications, cater to specific needs. Aluminum rods are designed for welding aluminum and its alloys, and high-temperature rods are used in situations that require heat resistance.

Quality control is a critical aspect of manufacturing, and automatic spray coating machines play a vital role in meeting stringent standards. These machines are designed to provide a consistent finish, ensuring that every product meets the desired specifications.

The Importance of Fume Extraction

2. Compliance Check Each ISO container must meet specific regulatory standards. During the survey, inspectors review the container's certification, ensuring that it meets international safety regulations and has a valid CSC (Container Safety Convention) certificate.

Expert testimonials reinforce the equipment's reputation for reliability and durability. Manufacturers investing in these systems often report a swift return on investment, not only through cost savings and enhanced throughput but also through a marked improvement in product quality and longevity. This assertion is supported by extensive research and field studies, confirming the equipment's ability to withstand rigorous operational demands while maintaining peak performance levels.

Professionals who have integrated automatic paint spraying equipment into their operations frequently highlight several transformative benefits. First and foremost is the significant reduction in labor costs. By automating the painting process, companies can reallocate human resources to tasks that require critical thinking and creativity, thereby improving overall operational efficiency. Additionally, automation mitigates the risks associated with manual paint application, such as exposure to harmful chemicals and inconsistent application results.

Whether it’s a wall mounted welding fume extractor for smaller workshops or a more complex central fume exhaust system for larger operations, these solutions offer effective means of keeping the air clean. Integrating a fume ventilation system directly with the robotic welders enhances the overall performance of both the system and the workers, promoting a healthier work environment and improving the longevity of the equipment.

In the realms of global trade and logistics, the efficiency of container transportation is paramount. The complexity of managing large volumes of goods across international borders calls for a systematic approach to ensure that every container reaches its destination timely and safely. This is where container transportation control equipment plays a crucial role. This article delves into the significance of such equipment and its impact on the logistics industry.

Benefits of Conducting ISO Container Surveys

2. Electronics Manufacturing In soldering processes, flux fumes can be toxic to health. By using portable fume collectors, companies can minimize inhalation risks for technicians, ensuring a safer workspace.

Ultimately, the decision to employ an automatic spray painting machine is one that underscores a commitment to quality, efficiency, and forward-thinking production strategies. Not only does it signify an alignment with cutting-edge technology, but it also positions your business as a leader in delivering products that meet high standards in craftsmanship and environmental consideration.

For industries such as automotive, aerospace, and consumer electronics, where aesthetic excellence and functionality are paramount, automatic paint spraying equipment offers an ideal solution. These industry sectors rely on the equipment's capacity to maintain high production volumes without compromising on quality. Moreover, these systems support a wide range of coatings, including water-based, solvent-based, and powder coatings, catering to diverse application needs and environmental considerations.

The Weight of the Container A Journey into Strength and Resilience

Risk Management and Security

Automated spray coating systems integrate cutting-edge technology with sophisticated engineering to deliver consistent and uniform coating applications across a variety of surfaces. Their precision is unmatched, thanks to advanced robotics and control systems that ensure each component receives the correct amount of coating material, reducing waste and ensuring uniformity and accuracy. This precision significantly reduces the need for rework and material consumption, resulting in substantial cost savings for manufacturers.

MIG welding, or Metal Inert Gas welding, is a widely used welding process that relies on a continuous feed of filler wire that is automatically fed through a welding gun. One significant aspect of MIG welding that is often overlooked is the importance of proper fume extraction, known in German as Rauchabsaugung. Effective fume extraction is crucial to maintaining a safe and healthy working environment for welders.

3. Accessibility Containers should be designed with features that facilitate easy access, such as open tops or removable sides, making it easier for workers to load and unload materials quickly.