Omega Fatty Acids

Omega Fatty Acids

Med Cities also offer opportunities for community engagement and education. Awareness campaigns about responsible pet ownership, animal hygiene, and preventive care are essential for fostering understanding between human and animal health. Workshops, seminars, and outreach programs can help educate the public about the importance of veterinary care within the broader context of health.

Respiron Poultry Medicine Pricing and Its Impact on the Industry

3. Allergy Management Identifying specific allergens is crucial in managing chronic coughing. Allergy testing can help, followed by targeted environmental changes or medications.

Pink Eye Medicine for Cattle A Comprehensive Guide

3. Facilitated Breathing By clearing mucus that might block airways, expectorants can improve airflow and facilitate easier breathing.

Preventive Measures

Ulcer Medication for Horses Understanding Options and Treatments

Prescription Medication for Horses Ensuring Health and Performance

1. Hormonal Regulation DOCP effectively aids in restoring hormone levels in dogs with Addison’s disease, which can significantly enhance their overall health and wellbeing.

When using expectorants, it is vital to follow the prescribed dosage and guidelines. Individuals should drink plenty of fluids while taking these medications, as hydration plays a critical role in mucus thinning. It is also important to understand that expectorants do not cure the underlying cause of the cough or congestion; rather, they offer symptomatic relief.

Conservative Treatments

It is important for goat owners to monitor their herds closely, especially during seasonal changes, as stress factors can predispose goats to respiratory infections.

Administering medications to dogs can be a challenge, especially if they are reluctant to take them. Here are some effective strategies to ensure your dog receives their medication

Prevention Strategies

In conclusion, while albendazole is a vital medication for treating various parasitic infections, the price and overall accessibility remain significant challenges, especially in low-income countries. Ensuring that the medication is affordable and available through various initiatives is essential for improving public health outcomes. Continued collaboration among governments, health organizations, and pharmaceutical companies will be critical in tackling the barriers to access, ultimately leading to a healthier population less burdened by parasitic diseases.

Managing pain in horses is an essential aspect of responsible horse ownership. By understanding the various types of pain relievers available and their respective effects, you can make informed decisions that promote your horse's well-being. Remember to work closely with your veterinarian to create a comprehensive pain management plan that addresses your horse's needs while minimizing risks related to medication. With the right approach, you can ensure your horse remains comfortable and healthy, allowing them to live a happy and active life.

5. Promotes Energy Levels Adequate levels of B vitamins help your cat maintain energy levels throughout the day. These vitamins play a vital role in metabolic processes, ensuring that your cat has the energy needed for playtime and daily activities.

1. Penicillins These are often used to treat skin infections and respiratory tract infections in dogs. They are generally well-tolerated and effective against a broad range of bacteria.

Dosage and Administration

1. Supports Immune Health

Conclusion

Recognizing the signs of diarrhea in chickens is crucial for early intervention. Symptoms include

The Role of Calcium

Aspirin, a well-known nonsteroidal anti-inflammatory drug (NSAID), is commonly used in human medicine to alleviate pain, reduce inflammation, and lower fever. Interestingly, aspirin also has applications in veterinary medicine, particularly for goats. Understanding the appropriate use of aspirin for goats is essential for any goat owner or caretaker, as it can significantly impact their health and wellbeing.

Before adding any vitamins or supplements to your dog's diet, it's crucial to consult your veterinarian. They can help determine the specific needs of your dog and ensure that any dietary changes are safe and appropriate. Additionally, excessive intake of certain vitamins can lead to toxicity, so professional guidance is important.

Just like humans, dogs can experience nausea for a variety of reasons. Whether it's due to motion sickness, an upset stomach, a reaction to medication, or other health issues, nausea can significantly affect your dog's well-being. Thankfully, anti-nausea medications are available to help alleviate this discomfort and improve their quality of life. Understanding the importance of these medications and how they work can empower dog owners to better care for their furry friends.

Young and growing animals have particularly high calcium requirements, as they are developing their skeletal structures. Lactating females also have increased calcium needs, as they must supply their offspring with sufficient nutrients. Moreover, certain breeds, such as large-breed dogs, are predisposed to calcium-related disorders, making proper supplementation critical.

When considering Bulldog Vitamins, it’s essential to assess your dog’s specific needs. Factors such as age, breed, size, and health conditions should influence your choice of supplements. For instance, puppies may require different nutrients compared to senior dogs, and larger breeds may benefit from joint support formulations. Consulting with your veterinarian can help you determine the best options for your canine companion.

The Importance of Worming Your Dog

In addition to topical treatments, injectable dewormers can also be effective in treating lice infestations. Ivermectin, moxidectin, and other anthelmintics targeting ectoparasites are commonly used. These treatments not only combat lice but also provide broader protections against other parasites, enhancing overall herd health.

Identifying Yeast Infections in Dogs

Causes and Risk Factors

Conclusion

Horses are often hosts to various species of internal parasites, including roundworms, tapeworms, and bots. These parasites can lead to significant health problems. Young horses and those with compromised immune systems are particularly vulnerable. Regular deworming helps to control parasite populations, which in turn supports overall health, productivity, and longevity.

4. Vitamin D This vitamin is essential for calcium absorption and bone health. It's often found in fish liver oils and fortified dog foods. If your homemade dog food lacks these, a vitamin D supplement may be necessary—however, consult your vet first, as too much can be harmful.

Infectious diseases like coccidiosis, which is caused by parasites that affect the intestinal tract, are particularly detrimental in layers. Symptoms include blood in droppings, lethargy, and weight loss, all of which can lead to significant economic losses. Vaccination and prophylactic measures are essential to prevent such infectious diseases.

Recognizing the Symptoms

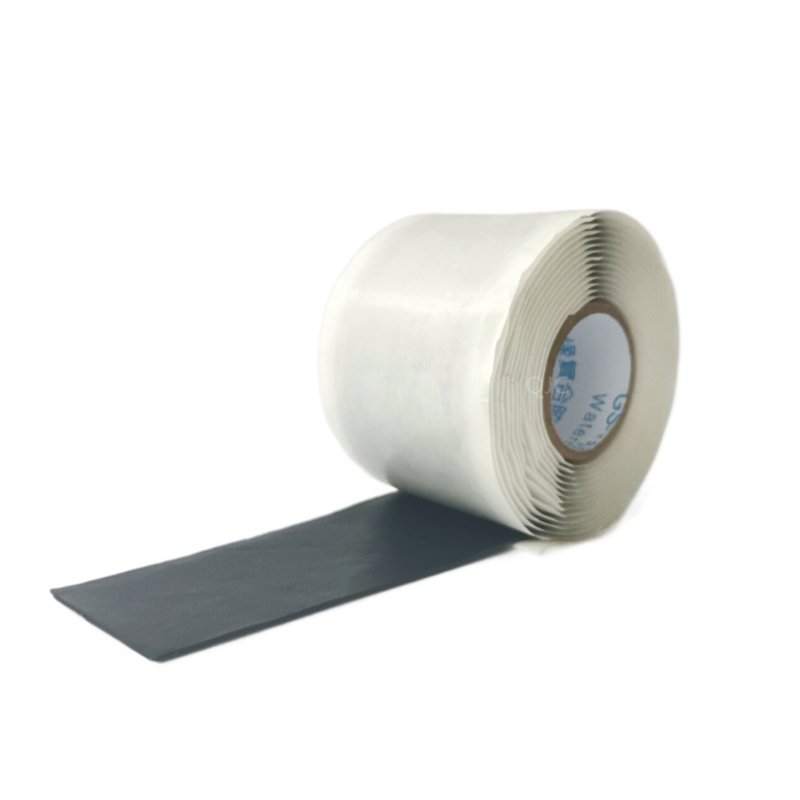

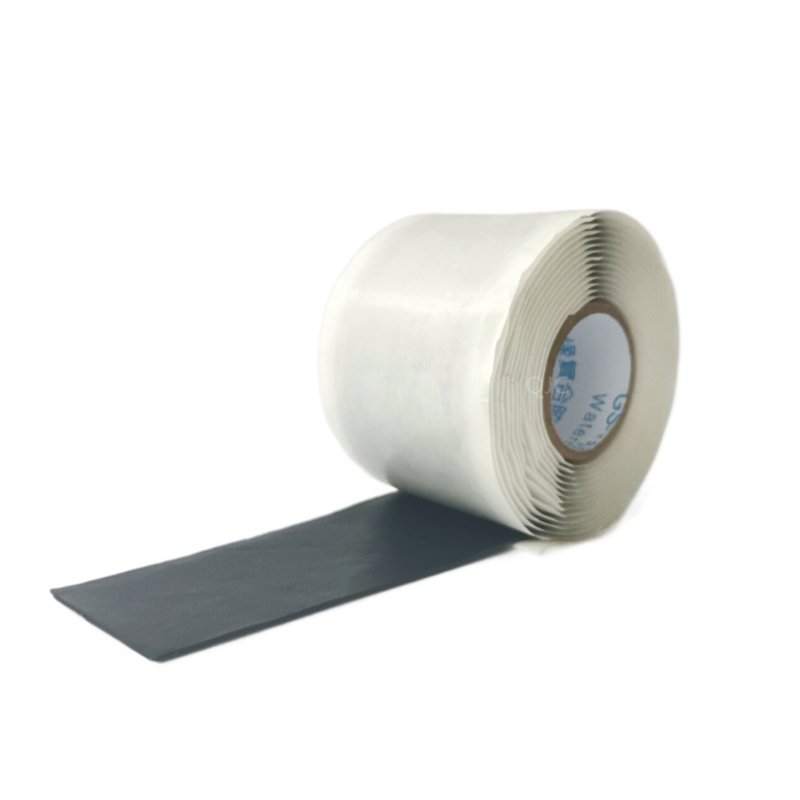

durable floor tape. Most tapes are self-adhesive, which means they can be applied quickly and easily without the need for any special tools or equipment. This makes it a cost-effective solution for businesses that need to regularly update their floor markings.

durable floor tape. Most tapes are self-adhesive, which means they can be applied quickly and easily without the need for any special tools or equipment. This makes it a cost-effective solution for businesses that need to regularly update their floor markings.Widths range from one-half of an inch (12 millimeters) to 6 inches (144 millimeters), and available colors are:

Conclusion

pvc hazard tape. It can withstand exposure to a wide range of chemicals, including acids, bases, solvents, and oils, making it an ideal choice for environments where chemicals are present. This characteristic ensures that the tape maintains its integrity and effectiveness over time, even in harsh conditions.

pvc hazard tape. It can withstand exposure to a wide range of chemicals, including acids, bases, solvents, and oils, making it an ideal choice for environments where chemicals are present. This characteristic ensures that the tape maintains its integrity and effectiveness over time, even in harsh conditions. It is used to mark and label wires, making it easier to identify different circuits and prevent accidental disconnection It is used to mark and label wires, making it easier to identify different circuits and prevent accidental disconnection

It is used to mark and label wires, making it easier to identify different circuits and prevent accidental disconnection It is used to mark and label wires, making it easier to identify different circuits and prevent accidental disconnection brown insulation tape. It's also invaluable for temporarily repairing damaged cables or insulation, providing a quick fix until a more permanent solution can be implemented.

brown insulation tape. It's also invaluable for temporarily repairing damaged cables or insulation, providing a quick fix until a more permanent solution can be implemented.It is used for making watertight seals, waterproofing joints, and temporarily repairing leaks in pipes, hoses and tubes.

This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations

This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations yellow and green electrical tape.

yellow and green electrical tape.We’ll also provide some tips on how to choose the right type of tape for your needs!