The 2023 edition, witnessed around 500 exhibiting companies from 50 countries, 17,500 sqm gross and 10,080 expected visitors. The show had an enriched conference program covering dairy, fish, poultry, eggs, cattle, calves, goat, and camels. More than 37 sessions, presentations and panel discussions delved into recent industry trends, challenges, and opportunities, providing invaluable insights for all attendees, in both the animal livestock production and the arable and controlled environment agriculture industry. One third of the visitors came from the UAE, with countries like Egypt, Iraq, Iran, Pakistan and Saudi Arabia ranking on top right after. At VIV MEA, suppliers and buyers from all the segments of the Feed to food chain are represented. This includes feed (ingredients) and animal health, animal husbandry, equipment for breeding, farming, slaughtering, processing and much more.

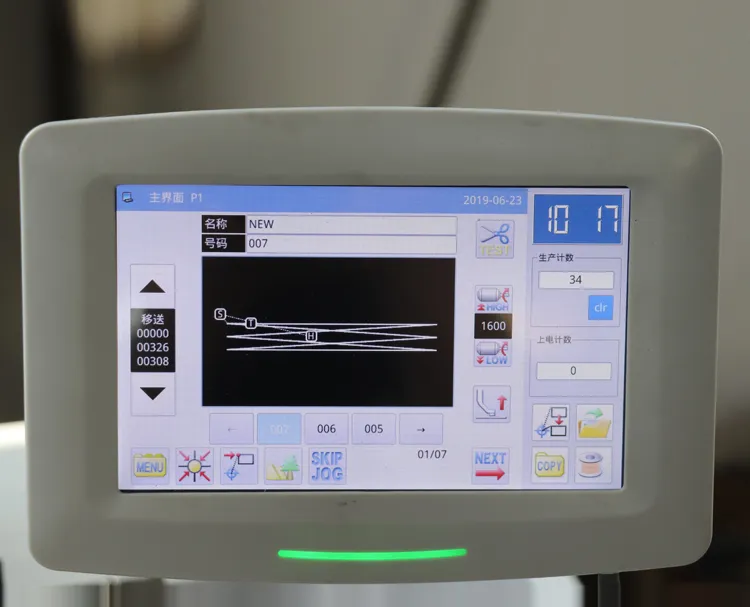

This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality

This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality This efficiency allows upholstery businesses to take on larger projects or cater to higher demand without compromising on quality