Potential Risks

Potential Risks

The dosage of albendazole varies based on the type of infection and the patient's age. For most intestinal nematodes, a single dose of 400 mg is often sufficient for adults, while children’s doses are typically based on body weight. In cases of more complex infections, such as neurocysticercosis, treatment might involve a longer regimen of albendazole, sometimes combined with corticosteroids to reduce inflammation.

Essential Poultry Medicine Products for Optimal Farm Health

Pain Relief Medications Non-steroidal anti-inflammatory drugs (NSAIDs) and other pain relievers can be prescribed to help manage pain and inflammation. In some cases, joint supplements containing glucosamine and chondroitin sulfate may also be recommended to support joint health.

In the world of agriculture, poultry farming, specifically chicken farming, has emerged as a crucial component of food production systems globally. As the demand for chicken meat and eggs continues to rise, maintaining the health and productivity of poultry flocks has become increasingly important. The integration of medicine in chicken farming is essential for ensuring the well-being of birds and the sustainability of the farming operation.

Goat Pneumonia Understanding and Management

Several classes of deworming medicines, also known as anthelmintics, are available for sheep. The most commonly used include

The administration of prescription medications should always be guided by a qualified veterinarian. Horses have unique physiological systems, and improper use of medications can have serious consequences. Veterinarians assess the individual needs of each horse, considering factors such as age, weight, health history, and the specific condition being treated. They provide tailored treatment plans and dosages to ensure safety and effectiveness.

- Regular Deworming Implement a deworming schedule based on fecal tests to monitor parasite loads.

Composition and Mechanism of Action

Natural Remedies For pet owners who prefer a holistic approach, there are various natural anti-inflammatory supplements that are available OTC. Ingredients such as turmeric and omega-3 fatty acids have been shown to have anti-inflammatory properties. Turmeric contains curcumin, which has been praised for its potential to reduce inflammation as well as providing antioxidant benefits. Omega-3 fatty acids, found in fish oil, can also help combat inflammation and promote overall health. These options are generally considered safe, but it’s still a good idea to consult a veterinarian.

One significant benefit of homemade dog food, even with the added supplements, is the freshness and quality control pet owners gain over their dog's diet. Commercial dog foods may contain preservatives and fillers, which aren’t necessary for your pet’s health. Homemade options allow you to select high-quality ingredients, free from questionable additives, which leads to improved overall health and wellbeing.

2. Flavor Options Many pets are reluctant to take their medications due to unpleasant tastes. Compounding pharmacies can add flavors that appeal to animals, making it much easier to administer medication, whether it’s chicken, tuna, or beef-flavored.

2. Turmeric Turmeric contains curcumin, a compound that possesses powerful anti-inflammatory effects. It may help reduce swelling and discomfort in joints, making it a popular ingredient in many horse joint supplements.

1. Anti-inflammatory Medications

1. Vitamin A This vitamin is vital for eye health, skin condition, and cell growth. A deficiency may lead to poor vision and skin issues.

Horse medicine, or equine medicine, is a specialized branch of veterinary medicine that focuses on the health and treatment of horses. This field encompasses a wide range of practices, from routine wellness care to complex medical and surgical procedures. Given the unique physiology and behavioral characteristics of horses, equine medicine requires a deep understanding of these magnificent animals and the challenges they face.

Anatomy of the Horse's Ear

For cases caused by dietary issues, farmers can take corrective measures by providing clean, fresh feed and water, adjusting their diet to reduce sudden changes, and ensuring that the feed is of high quality and free from mold or toxins. Offering probiotics can also help restore normal gut flora in chickens and support digestive health.

3. Vitamin D

Reptiles, ranging from vibrant chameleons to slithering snakes, are fascinating creatures that require specialized care to thrive in captivity. One of the critical components of maintaining their health is ensuring they receive a balanced diet, which can often be supplemented with multivitamins. Just like humans and other animals, reptiles can suffer from nutritional deficiencies if they do not receive the right vitamins and minerals in their diet. This article will explore the significance of reptile multivitamins, their essential components, and how they contribute to the overall well-being of these enchanting creatures.

3. Apply Antibiotic Ointment After cleaning, applying a dog-safe antibiotic ointment can help prevent infection. Always choose medications specifically formulated for dogs, as human products may contain harmful ingredients.

Veterinarians often recommend alternative treatments and preventive measures for managing diarrhea in horses. These can include dietary adjustments, hydration support, the use of probiotics, and medications specifically formulated for equines. For instance, electrolytes can be offered to rehydrate a horse suffering from diarrhea, while probiotics may help restore healthy gut flora.

Before starting any OTC treatment, always consult your veterinarian, especially if your dog is on other medications or has pre-existing health conditions. Additionally, always follow dosing instructions carefully to avoid adverse effects.

1. B Vitamins Water-soluble vitamins, particularly B vitamins, play an essential role in energy metabolism and overall health. Dogs with kidney disease often suffer from loss of appetite and may experience weight loss, which can lead to deficiencies in these vitamins. Supplementing with B vitamins, such as B12 and B6, can help improve appetite, energy levels, and support red blood cell production.

The process of euthanasia itself is designed to be as peaceful and gentle as possible. In most cases, it involves administering a sedative followed by an injection of a euthanasia solution, typically consisting of an overdose of anesthetics. This ensures the dog falls asleep comfortably before the final act of compassion is performed. Veterinary clinics often provide a serene environment for this process, allowing owners to be with their pets in their final moments—a privilege that can provide solace and closure.

Alternative Medicine for Dogs A Holistic Approach to Canine Health

20-22 NOVEMBER

Pharmacological Treatment Options

When using OTC medications, accurate dosing is essential. Always refer to guidelines provided by veterinarians or pharmaceutical labels. The size and health status of your goats will influence the correct dosage. For any new medication, it’s wise to conduct a trial run under the guidance of a vet to monitor the goat’s reaction.

Treatment Options

4. Reinforce the Behavior Once your dog successfully presses the button for a reward, reinforce this behavior by consistently praising them and providing a treat.

4. Record Keeping Keeping detailed records of antibiotic use helps farmers monitor treatments and understand patterns of disease. This information is also crucial for veterinary oversight and compliance with regulations regarding antibiotic use in livestock.

Homeopathy

Conclusion

One of the primary aspects of cattle veterinary medicine is preventive health care. This includes vaccination programs to protect against infectious diseases such as brucellosis, bovine viral diarrhea (BVD), and infectious bovine rhinotracheitis (IBR). Regular vaccinations are essential in maintaining herd health and preventing outbreaks that could have devastating effects on cattle populations and farmers' incomes. Furthermore, routine health checks enable early detection of potential health issues, allowing for timely intervention.

User Experience and Administration

The dosage of albendazole for dogs can vary depending on the specific condition being treated, the type of parasite, and the dog's weight. A general guideline suggests administering albendazole at a dosage of 5 to 10 mg per kilogram of body weight. For example, a 20 kg dog might receive a tablet containing 100 mg of albendazole, usually given once or twice daily for 3 days. However, it is crucial to consult your veterinarian to determine the appropriate dosage for your dog’s individual needs.

Veterinary Medicine for Goats A Comprehensive Overview

Medicine for Pneumonia in Cattle

Fiberglass septic tanks may present challenges in terms of access for maintenance. The tanks are often lighter and more flexible than their concrete counterparts, making them tougher to work with once installed. This can complicate the maintenance process, as technicians might find it more difficult to perform necessary inspections and repairs. This inconvenience can translate into higher long-term costs for homeowners, as they may need to schedule more frequent services to mitigate the issues arising from these challenges.

Environmental Considerations

steel water tank 1000 ltr price. These added features come at an extra cost but provide substantial benefits in terms of energy savings and health protection.

steel water tank 1000 ltr price. These added features come at an extra cost but provide substantial benefits in terms of energy savings and health protection.FRP winding is a manufacturing technique wherein continuous fibers, often glass or carbon, are wound around a mold or core, which can be cylindrical, conical, or even spherical. The fibers are typically pre-impregnated with resin, which cures and hardens upon setting, resulting in a finished composite product that combines durability and lightweight properties. This process enables the production of a wide range of items, including pipes, tanks, pressure vessels, and various structural components.

In today’s eco-conscious world, the environmental impact of materials is an increasingly important consideration. Stainless steel 316 is recyclable and made from a high percentage of recycled content, thus lessening the environmental footprint compared to alternatives such as plastic. Additionally, its long service life reduces the frequency of replacements, further contributing to sustainability efforts.

One of the primary reasons for the rising popularity of nail care is the growing recognition of self-grooming as an integral aspect of one’s identity. A well-groomed set of nails not only showcases hygiene but also enhances one’s overall appearance. In many cultures, nails that are clean and polished are considered a sign of professionalism and care. Whether in the office or at social events, well-maintained nails can leave a lasting impression.

- Site Safety Ensuring that the work area is clear of obstacles and potential hazards will help mitigate risks associated with the use of these powerful tools.

One of the most significant advantages of steel water tanks is their exceptional durability. Constructed from high-quality materials, these tanks can withstand extreme weather conditions, including heavy rainfall, wind, and even seismic activity. Unlike plastic tanks, which can become brittle over time, steel tanks offer a long lifespan and require minimal maintenance. Their resistance to corrosion, especially when treated with protective coatings, allows them to remain functional for several decades, making them a cost-effective investment in the long run.

A 300-gallon stainless steel water tank also offers superior thermal insulation compared to other materials. Stainless steel can help maintain water temperature, which is beneficial in various contexts, such as aquaculture or for hot water systems. This temperature stability can enhance efficiency and provide better overall performance for your needs.

1. Corrosion Resistance FRP pipes are highly resistant to a wide array of corrosive substances, including acids, alkalis, and salts. This resistance extends the lifespan of the pipe and minimizes maintenance costs.

The choice of raw materials significantly affects the overall cost of the pultrusion process. Fiberglass and carbon fiber reinforcements, along with resins, must be sourced and may fluctuate in price based on market conditions. Establishing long-term relationships with suppliers can reduce costs, but businesses should be prepared for price variations. Additionally, the formulation of the resin used can impact not just material costs but also processing times and end-product qualities, which in turn influences overall productivity and profitability.

The Versatility of Black Steel Iron Wire

The nails that held them together were more than mere fasteners; they were the threads that bound together a global network of trade and exchange The nails that held them together were more than mere fasteners; they were the threads that bound together a global network of trade and exchange

The nails that held them together were more than mere fasteners; they were the threads that bound together a global network of trade and exchange The nails that held them together were more than mere fasteners; they were the threads that bound together a global network of trade and exchange square boat nails factories.

square boat nails factories.Applications of 5.5 mm Iron Wire Coils

Finally, local market conditions and seasonal trends can also influence sink plate prices. During peak renovation seasons, prices may increase due to higher demand. Conversely, during off-peak periods, consumers might find better deals as retailers seek to move inventory.

1. Strength-to-Weight Ratio Fibreglass has an excellent strength-to-weight ratio compared to traditional materials like steel or aluminum. This feature makes 8mm fibreglass rods easy to handle while still providing the necessary support and durability.

5. Health and Safety With an emphasis on public health, it’s crucial to use materials that do not leach harmful substances into water supplies. FRP tanks are non-toxic and meet health standards, ensuring water quality is maintained. Their smooth interior surfaces also prevent algae and bacterial growth, which can be a risk in traditional water storage systems.

Hard drawn bright twisted nail wire is made from high-quality steel, drawn to achieve increased tensile strength and then twisted to ensure that it maintains its structural integrity during use. The bright aspect refers to the wire's surface, which is polished to ensure a smooth finish, free of imperfections. This not only enhances the aesthetic quality of the wire but also improves its adhesion to coatings and paints, making it a preferred choice for many manufacturers.

Wire mesh, a versatile product used in various industries, plays a crucial role in construction, agriculture, fencing, and industrial applications. Its dynamic nature and utility have made it a staple material for many businesses. When considering the purchase of wire mesh, understanding its pricing structure is essential. This article offers a detailed overview of the factors influencing the wire mesh pricelist and provides insights into making informed purchasing decisions.

- Reputation Look for suppliers with a proven track record and positive customer reviews.

Dipped galvanized iron wire is a type of wire that has been coated with a layer of zinc through a process called galvanization. This process helps to protect the iron wire from corrosion and rust, making it much more durable and long-lasting in various applications.

This type of fencing is not limited to a single purpose; its versatility makes it suitable for various applications. For residential use, a 6x6 welded wire mesh fence serves as an excellent boundary solution for gardens, pool areas, and yards. It keeps pets and children safe while providing unobtrusive visibility. For commercial enterprises, it's an effective way to protect construction sites, warehouses, agricultural fields, and even livestock enclosures. Its open design allows for ample airflow and visibility, which is crucial in many settings.

2x4 Welded Wire Mesh The Ideal Choice for Various Applications

Welded wire mesh is a versatile material that finds applications in various industries due to its durability, strength, and flexibility. Among the different types of welded wire meshes available in the market, the 2x4 welded wire mesh stands out as one of the most popular choices for many construction and industrial projects.

Understanding Hexagonal Meshes

One of the key advantages of the 2x4 welded wire mesh is its strength. The welded construction creates a sturdy and rigid structure that can withstand heavy loads and impacts. This makes it ideal for use in applications where structural integrity is crucial, such as in the construction of concrete slabs, walls, and columns.

Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability

Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability 2 inch fiberglass tube.

2 inch fiberglass tube.1. Construction Industry In construction, binding galvanized wire is extensively used for tying rebar (reinforcing bar) and securing building materials. Its strong binding capability ensures that structures remain stable and resilient during the construction process. Additionally, it is also utilized for forming shapes and frameworks in concrete applications.

However, like any construction material, iron lost head nails come with certain considerations. For instance, the need for precision in installation is paramount, as misalignment can weaken the joint. Additionally, factors such as the type of wood and environmental conditions can affect the performance of these nails over time. It is essential to ensure that the correct size and type of nail are selected for the specific application to maximize their effectiveness.

Beyond their practical applications, coiled clout nails are becoming popular due to their environmental impact. Many manufacturers are now producing these nails using recycled materials and sustainable practices. This aligns with the growing trend in the construction industry toward sustainable and eco-friendly building practices. By choosing coiled clout nails, builders can contribute to a reduced carbon footprint while ensuring that their projects are sturdy and reliable.

One primary benefit of using concrete and steel nails in construction is the enhanced safety of structures. Buildings and infrastructures constructed with high-quality concrete are less susceptible to natural disasters such as earthquakes and floods, which are common in many regions of China. Steel nails contribute to this safety by ensuring that different components of a structure remain intact during such events.

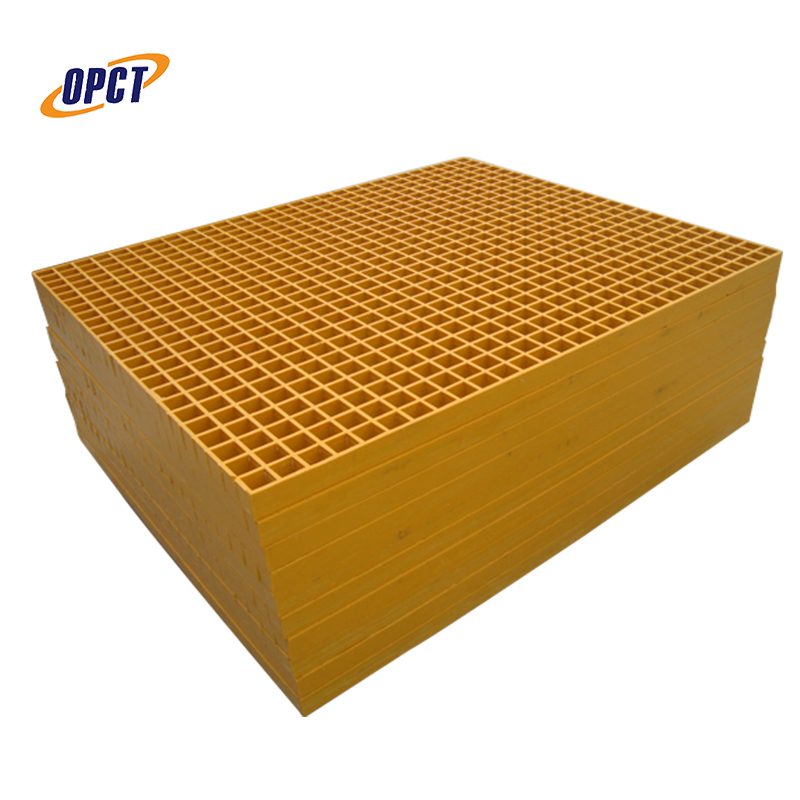

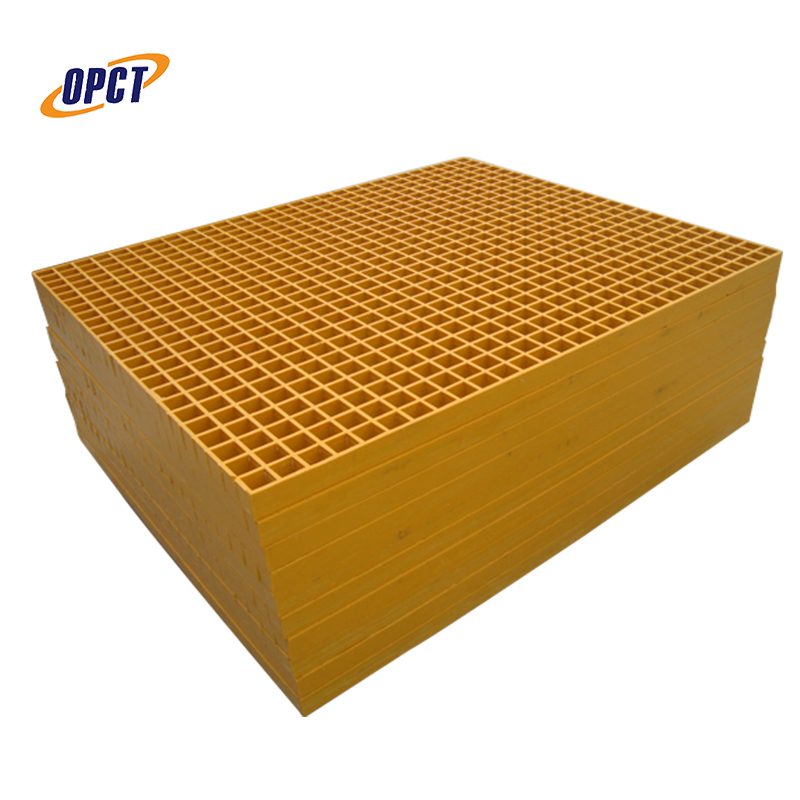

One of the key advantages of frp tray is its ability to withstand harsh chemical environments. The fiberglass reinforced plastic material is resistant to corrosion from acids, alkalis, and other chemicals, making it an ideal choice for industries that handle corrosive substances. This resistance to chemical attack helps to prolong the lifespan of the tray, reducing maintenance costs and ensuring reliable performance over time.